DRV8424P - Hardware details

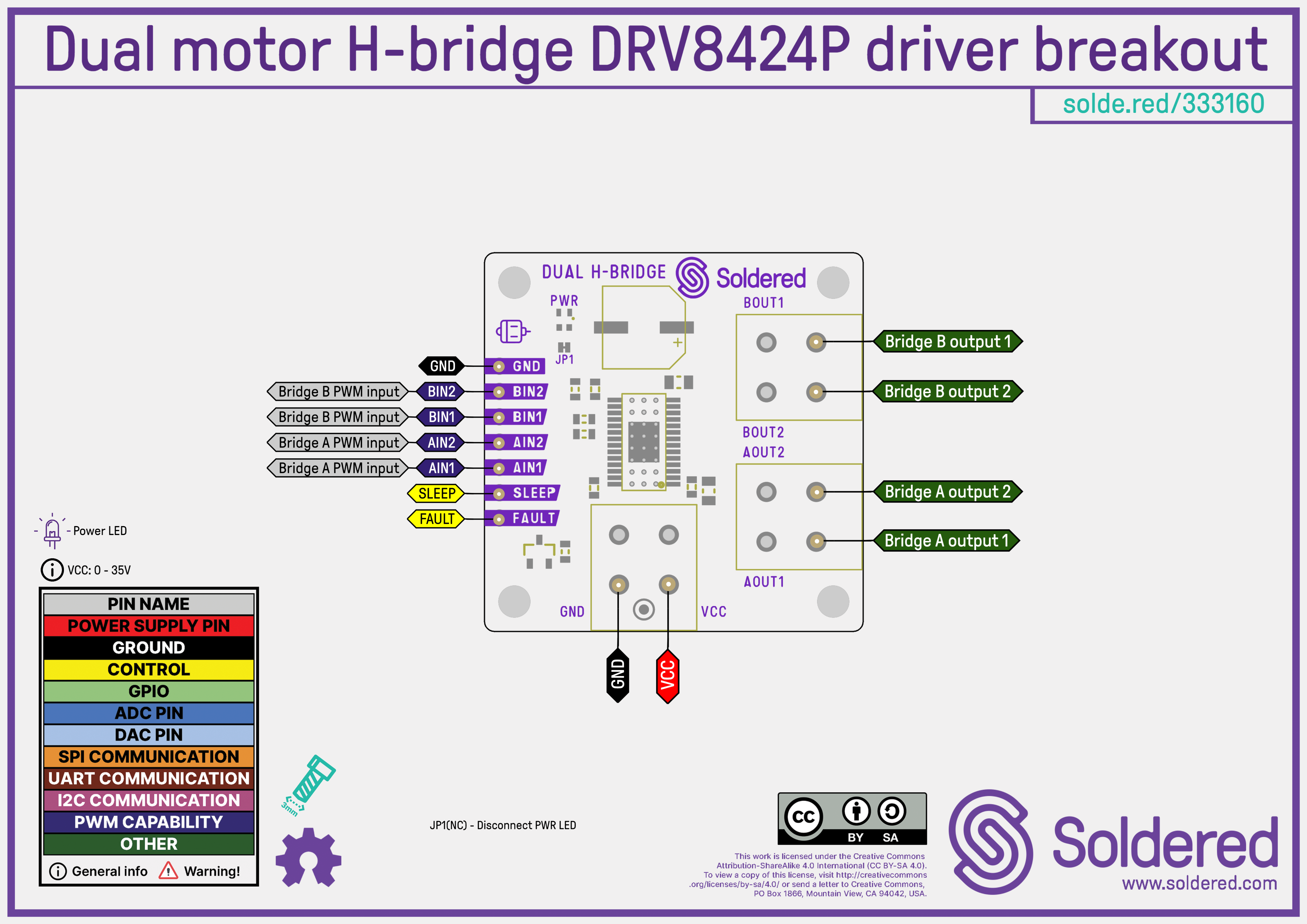

Pinout

Pin Details

| Pin Marking | Pin Name | Description |

|---|---|---|

| GND | Power/Ground | Common ground for both logic and motor supply. |

| VCC | Power Input | Motor voltage supply input (4.5V to 33V). |

| AIN1 | Logic Input | H-bridge A control input 1 – controls motor A direction. |

| AIN2 | Logic Input | H-bridge A control input 2 – controls motor A direction. |

| BIN1 | Logic Input | H-bridge B control input 1 – controls motor B direction. |

| BIN2 | Logic Input | H-bridge B control input 2 – controls motor B direction. |

| SLEEP | Logic Input | Active-low input. Pull low to enter low-power sleep mode. |

| FAULT | Logic Output | Open-drain output. Goes low during a fault (e.g., overcurrent, thermal). |

| Bridge A Output 1 | Motor Output | Output terminal 1 of H-bridge A (Motor A). |

| Bridge A Output 2 | Motor Output | Output terminal 2 of H-bridge A (Motor A). |

| Bridge B Output 1 | Motor Output | Output terminal 1 of H-bridge B (Motor B). |

| Bridge B Output 2 | Motor Output | Output terminal 2 of H-bridge B (Motor B). |

Dimensions

- Board dimensions: 28 × 22 mm (1.1 × 0.9 inch)

- Pin hole diameter: 1.5 mm

- Mounting holes: M3 (3.2 mm diameter)

- Compatible with LEGO system 🧱

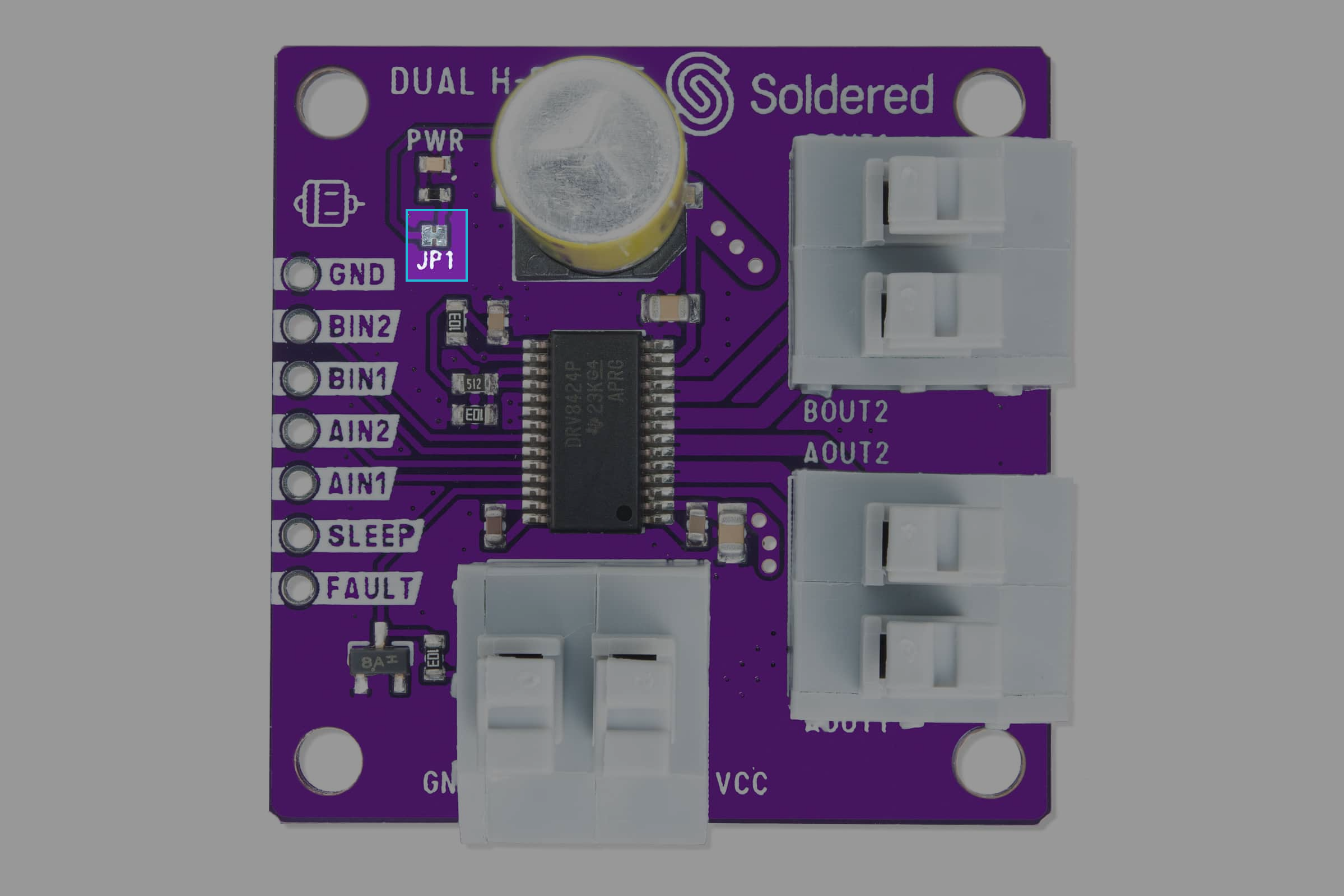

Jumper Details

This board contains one solder jumper:

JP1

| Jumper | Default State | Function |

|---|---|---|

| JP1 | NC (closed) | Connects the power indicator LED. |

Hardware repository

Schematics, KiCad project files, Gerber outputs, and more are available in the GitHub repository:

DRV8424P Dual Motor Driver Hardware Repository

Hardware design files for the dual motor H-bridge DRV8424P driver breakout board.

Available files

CAD Files

The project is designed using KiCad, an open-source PCB suite. The .kicad_pro file contains the full schematic and board layout.

Schematic

The schematic diagram in .pdf format can be found in the OUTPUTS folder.

BOM (Bill of Materials)

- A

.csvfile listing all components, quantities, and part numbers. - An interactive BOM (

.html) with visual identification of components on the board.

3D Model

A .step file of the PCB is provided for use in CAD and mechanical modeling applications.

Gerber Files

Used for manufacturing, the Gerber files include:

- Copper layers (

.Cu.gbr) - Solder mask layers (

.Mask.gbr) - Silkscreen layers (

.Silkscreen.gbr) - Paste layers (

.Paste.gbr) - Drill files (

.drl) - Board outline (

.Edge_Cuts.gbr) - Gerber job file (

.gbrjob)

Compliance

Includes necessary documentation to certify safety and legal compliance:

- CE

- UKCA

- Safety Instructions (EN & DE)

- Info.txt – includes SKU, HS code, and manufacturing details