Ltr 507 – Hardware details

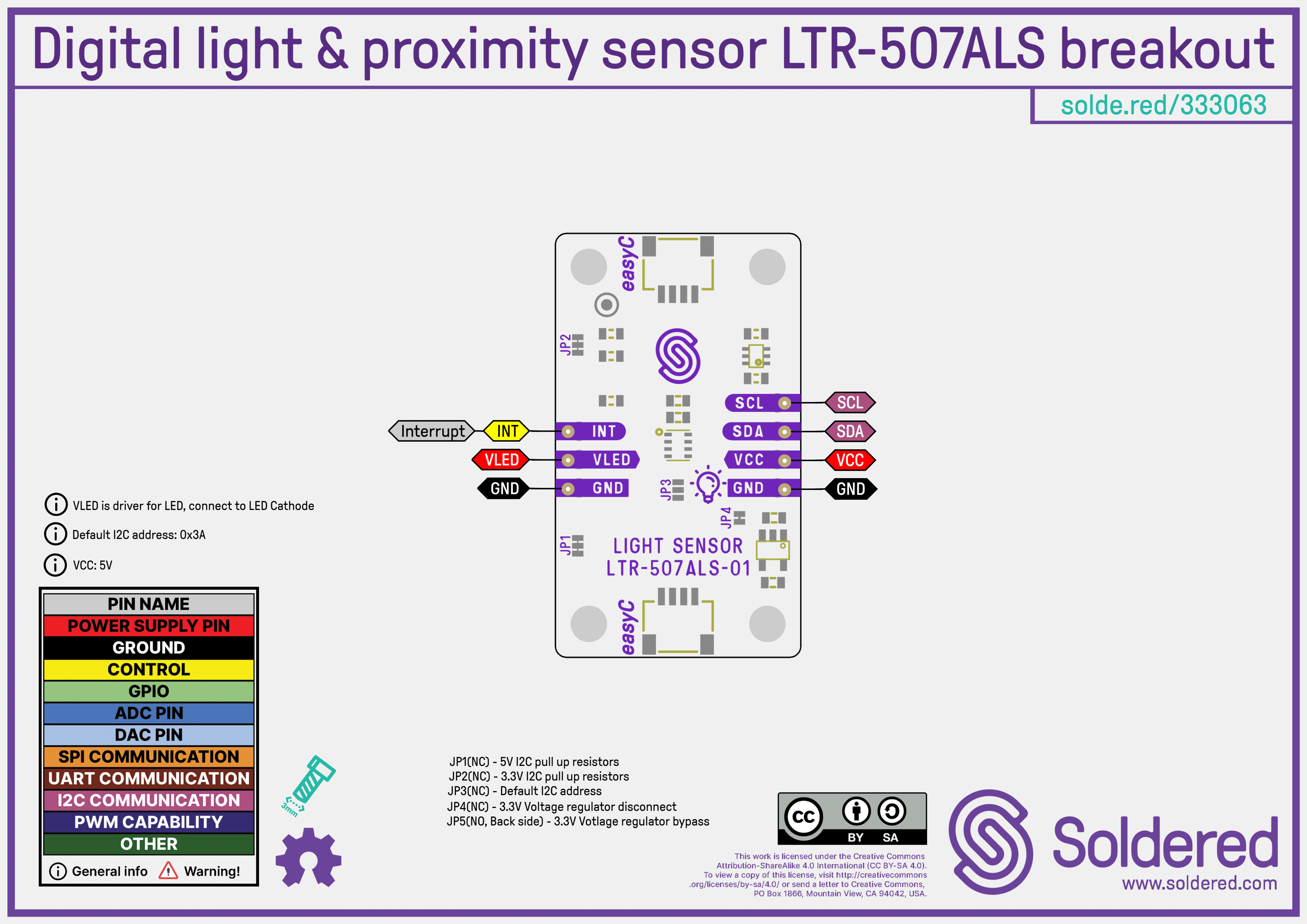

Pinout

Click here for a high-resolution image of the pinout.

Pin details

| Pin Marking | Pin Name | Description |

|---|---|---|

| VCC | Power | Supply voltage (both 5V and 3V3 are supported). |

| GND | Ground | Common ground for power and signals. |

| SDA | Data | I2C data line for communication. |

| SCL | Clock | I2C clock line for communication. |

| VLED | Power | Current supply for the proximity LED. |

| INT | Control | Interrupt signal (from LTR-507). |

Qwiic (formerly easyC)

Qwiic (formerly easyC) details and specifications

Learn about hardware specifications, compatibility, and usage of the Qwiic connector.

Power Consumption

The LTR-507ALS-01 sensor is designed for low power consumption, making it suitable for battery-powered applications.

- Low-power mode: 0.2mA

- Active mode: 2.3 mA

Dimensions

- Board Dimensions: 38 × 22 mm (1.5 × 0.9 inch)

- Header Pin Holes: 1.5 mm

- Screw Holes: Designed for M3 screws (3.2 mm diameter)

- Soldered boards are LEGO compatible! 🧱

Jumper Details

This board contains hardware jumpers. See below for their locations and functions:

| Jumper | Default State | Function |

|---|---|---|

| JP1 | NC (Normally closed) | Connects the SDA/SCL pull-up resistors to 5V for I2C communication. |

| JP2 | NC (Normally closed) | Connects the SDA/SCL pull-up resistors to 3.3V for I2C communication. |

| JP3 | NC (Normally closed) | Address selection (default I2C address 0x3A). |

| JP4 | NC (Normally closed) | When connected, the voltage regulator is powered by 5V, which steps it down to 3.3V for the IC. |

| JP5 | NO (Normally open) | When shorted, it bypasses the voltage regulator, allowing the board to be powered directly from 3.3V via headers. Ensure that JP4 is disconnected if JP5 is connected. |

Address Selection

The LTR-507 sensor has a configurable 7-bit I2C address, determined by the state of the SEL pin. Depending on how the pin is connected, the sensor will respond to one of three possible addresses:

| SEL Pin State | I2C Address |

|---|---|

| GND (0) | 0x23 |

| VCC (1) | 0x26 |

| Floating | 0x3A |

If your I2C scanner detects address 0x3A, this means the SEL pin is floating (not connected to either GND or VCC).

Hardware repository

Schematics, KiCad files, Gerber files, and more can be found in the GitHub repository:

Digital light & proximity sensor LTR-507 breakout Hardware Design

GitHub hardware repository for this product

The hardware repository contains everything you need to understand, modify, or manufacture the board. The different output folders are versioned. You can check which board version you have specifically by finding the version mark on the PCB.

Below is an overview of the available files.

CAD files

We use KiCad, an open-source PCB design tool. You can open and edit the .kicad_pro project file, which includes both the schematic and PCB layout.

The PANEL files are used internally for production.

Schematic

The OUTPUTS folder contains the schematic in .pdf format, exported from KiCad.

BOM (Bill of Materials)

The bill of materials (BOM) is provided in two formats:

- A standard

.csvtable, listing all components, part numbers, and values. - An interactive BOM (

.html) that visually highlights each component on the PCB, making it easy to locate and reference parts.

3D files

A 3D model of the PCB is available in .step format, allowing you to inspect the board design in CAD software.

Gerber files

Gerber files are essential for PCB manufacturing, as they contain precise instructions for each layer of the board. The repository includes standard Gerber outputs in a .zip file, such as:

- Copper layers (

.Cu.gbr) – Defines the traces and pads on the board. - Solder mask layers (

.Mask.gbr) – Specifies the protective solder mask. - Silkscreen layers (

.Silkscreen.gbr) – Contains text and component markings. - Paste layers (

.Paste.gbr) – Used for stencil fabrication in SMD assembly. - Drill files (

.drl) – Provides drilling coordinates for vias and holes. - Board outline (

.Edge_Cuts.gbr) – Defines the shape of the PCB. - Gerber job file (

.gbrjob) – Describes the set of Gerber files used for production.

These files are ready for fabrication and can be used in PCB manufacturing.

Compliance

The Compliance section includes important regulatory and safety documentation for this product. These files ensure compliance with relevant industry standards and legal requirements.

- CE – Certification document confirming compliance with EU safety, health, and environmental requirements.

- UKCA – UKCA (UK Conformity Assessed) certification for the UK market.

- Safety Instructions – Safety guidelines and precautions in both English and German.

- Info.txt – Contains product details such as SKU, country of origin, HS tariff code, and barcode.